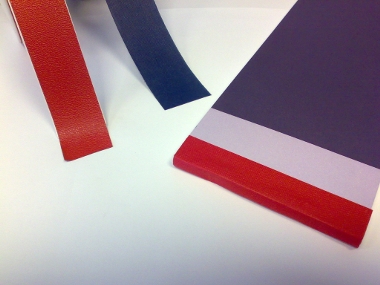

Product Description :

530 Ruby |

532 Red |

535 Cherry |

538 Claret |

534 Maroon |

539 Berry |

563 Dark Blue |

569 Paris Blue |

568 Prussian Blue |

500 White |

588 Sapphire Blue |

565 Blueberry |

586 Aubergine |

580 Amethyst |

509 Buttermilk |

552 Green |

553 Dark Green |

519 Oatmeal |

515 Brown |

524 Dark Brown |

518 Sunshine |

525 Mandarin |

570 Black |

544 Graphite |

541 Grey |

| Dimensions(width/length) | Rolls per case | Order Volumes |

| 50mm x 20m | Lead time Black 4-5 weeks, Green 10-12 weeks, multiples Black 532 rolls,Green multiples of 855 rolls | |

| 25mm x 50m | 1 | Sold as individual roll |

| 25mm x 50m | 48 | 29x29x31cm/11 kg |

| 30mm x 50m | 50 | MOQ 576 rolls for 30mm wide when in any colour other than Black or Blue. 8 Weeks lead time |

| 35mm x 50m | 48 | 35x35x31cm / 14.3 Kg |

| 38mm x 50m | 32 | 37x36x32cm/16.1kg |

| 50mm x 50m | 36 | 37x36x32cm/16.1kg |

| 63mm x 50m | 24 | 35x35x31cm / 14 Kg |

| 65mm x 50m | 24 | 35x35x31cm / 14 Kg |

| 30mm x 80m | 30 | lead 4 weeks, 32x32x31cm, 12kgs each |

| 98mm x 100m | 8 | lead time 3 weeks, 100 rolls moq |

| 25mm x 150m | 11 | 29 x29 x 29 cm - 7kg Lead time 8-10 weeks |

| 38mm x 150m | 7 | 29 x29 x 29 cm - 7kg Lead time 8-10 weeks |

| 45mm x 150m | 6 | Moq 63 rolls,lead time 6 weeks, case -29x29x29cm- 8kgs |

| 50mm x 150m | 5 | Moq 57 rolls,lead time 6 weeks, case -29x29x29cm- 8kgs |

| 70mm x 150m | 4 | 84 rolls (moq) grey heatseal (wound inside), 25x25x30cm -8kg lead time 12 weeks |

| 73mm x 150m | 4 | lead time 3weeks,120cmx80cmx45cm - 119 kg |

| 74mm x 150m | 4 | lead time 3weeks,120cmx80cmx45cm - 119 kg |

| 89mm x 150m | 8 | lead time upto 14 weeks, 42x42x22cm@18kg/case |

| 98mm x 150m | 8 | lead time 3 weeks |

| 100mm x 150m | 6 | moq 54 rolls, lead time upto 14 weeks (order multiple of 9) Case 42x34x22cm - 15kg |

| 24mm x 200m | 22 | lead time 9 weeks |

| 30mm x 200m | 22 | MOQ 120 rolls, 1kg per roll - lead time 25 days, case 43 x 22 x 35cm, 23kg case |

| 38mm x 200m | 7 | 29x29x29cm/10kg |

| 48mm x 200m | 6 | 29x29x29cm/12kg lead time 6-8 weeks MOQ 40 rolls, order multiples of 20 rolls |

| 50mm x 200m | 6 | 29x29x29cm/12kg lead time 6-8 weeks MOQ 40 rolls, order multiples of 20 rolls |

| 74mm x 200m | MOQ 65 rolls @ 2.74 kg per roll, lead 3-4 weeks | |

| 76mm x 200m | MOQ 65 rolls @ 2.74 kg per roll, lead 3-4 weeks | |

| 78mm x 200m | 36 rolls MOQ, Case 25x25x30 @ 12kg each | |

| 80mm x 200m | 4 | MOQ 60 rolls, lead 4 weeks, 9.9kg per case |

| 89mm x 200m | 4 | MOQ 55 rolls @ 2.92 kg per roll Lead 3-4 weeks. |

| 102mm x 200m | 4 | MOQ 45 rolls, |

| 102mm x 200m | 4 | MOQ 45 rolls, |

| 30mm x 225m | Moq 128 rolls Lead time up to 14 weeks, No samples available as special manufacture | |

| 73mm x 225m | MOQ 52 rolls lead time 10-12 weeks | |

| 76mm x 225m | 4 | |

| 89mm x 225m | ||

| 30mm x 250m | 31 | |

| 40mm x 250m | 24 | |

| 50mm x 250m | 5 | MOQ 57 rolls per colour (multiples of 57), Case 29x29x29cm 12kg, Lead 8-10 weeks |

| 72mm x 250m | 4 | Moq 52 Case size 29x29x29cm - 12kg, Lead 10-14 weeks |

| 73mm x 250m | 4 | MOQ 39 rolls lead time 10-12 weeks, 12.5kg per case |

| 76mm x 250m | 3 | case 12kgs,42x42x22cm, MOQ 52 rolls |

| 80mm x 250m | 3 | Moq 60 rolls per colour. Larger quantities in multiples of 48 rolls Lead 6 weeks |

| 81mm x 250m | 3 | MOQ 36 rolls per colour (multiples of 36) Carton size 29x29x29cm-12kg/ctn Lead 8-10 weeks |

| 86mm x 250m | 2 | case 9kgs,42x42x22cm, MOQ 55 rolls, comes in multiples of 44 rolls |

| 274mm x 250m | 2 | |

| 25mm x 330m | 11 | 29x29x29cm/14kg MOQ 39 rolls Lead time 4 weeks |

| 28mm x 330m | 10 | core size is 76mm. Case :29x29x31cm@ 14 kg |

| 30mm x 330m | 9 | Outside diameter 285mm |

| 38mm x 330m | 7 |

570 Black and 588 Sapphire Blue << STOCK IMAGES >>

50m length rolls: Stock line or short lead time. Sold as individual rolls or in cases

330m length rolls: Stock line or short lead time. Minimum: One cut out of 950mm wide log roll = 38 rolls 25mmx330m or equivalent.

(Part cases will have to be supplied).

530 Ruby, 552 Green and 569 Paris Blue

50m length rolls: Limited stock line or lead time about 6 weeks. Minimum: Full case quantity.

330m length rolls: Limited stock line or lead time about 6 weeks. Minimum: One cut out of 950mm wide log roll = 38 rolls 25mmx330m or equivalent.

(Part cases will have to be supplied).

Other Colours

50m length rolls: Minimum: 760 rolls 25mmx50m or equivalent. Lead time up to 12 weeks.

330m length rolls: Minimum: 114 rolls 25mmx330m or equivalent. Lead time up to 12 weeks.

(Part cases will have to be supplied for both 50m and 330m rolls).

Applications:

|

| The rolls of tape must be stored flat on their cut edges in the original packing until required for use, and must be protected from dust, heat, moisture, direct sunlight, corrosive and solvent fumes. Under these conditions, the storage lift of the tape in a temperate climate will be not less than two years. Storage in more severe, e.g. Tropical, climates we do not recommend storage for more than six months. |

Features and Benefits:

Can be used up to 70 ℃

They require only gentle pressure to adhere to almost any clean dry surface

Technical Performance:| Description | Value / Units |

| Thickness adhesive and carrier | 115-120 g/m2 (0.18mm) |

| Thickness adhesive only | 45 g/m2 (0.045mm) |

| 180 degree peel adhesion (Open Side) | 1200 N/m |

| Polyester loop tack (Open Side) | 1300 N/m |

| Release from self | 10 N/m |

| Service temperature | -10 to +70 ℃ |

| Recommended application temperature | +5 to +25 ℃ |

| Sheer adhesion 1Kg @23 ℃ | 48 hours |

| Hot Melt Rubber Pressure Sensitive Adhesive | 160 micron |

| Core diameter | 76 mm |

| Thickness | 0.25 mm |

| Breaking strength | 71 N/cm |

| Elongation at Break | 4 % |

| Adhesion to Steel | 6.0 N/cm |

| Adhesion to backing | Very low for easy wind |

| Shelf life | 12 months |

| Test Methods | BS 7116 |

|

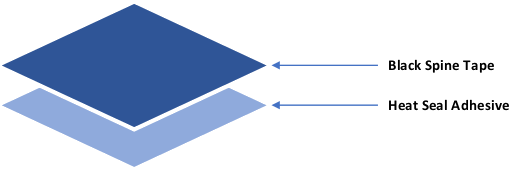

This spine tape product is a embossed paper. It has excellent durability and scuff resistance, may be printed using hot foil stamping, screen-printing and offset printing. This product is used to form decorative spines on small books, chequebooks and identification documents. It may also be used for complete covers. The rolls of tape must be stored flat on their cut edges in the original packing until required for use, and must be protected from dust, heat, moisture, direct sunlight, corrosive and solvent fumes. Under these conditions, the storage lift of the tape in a temperate climate will be not less than two years. Storage in more severe, e.g. Tropical, climates we do not recommend storage for more than six months. |

| Properties | Printability | Applications / Decorative spines on | Typical Properties |

|

|

|

|

|

| Heat Seal Adhesive : PCC82 is a versatile heat seal adhesive which will heat seal to a wide range of fibrous surfaces such as paper and board. PCC82 has an activation temperature of 70 ℃ and a softening point of 40 ℃ The above gave fibre tear bond when heat sealed for 10 seconds at 75 ℃. It will heat seal up to a temperature of 150 ℃ PCC82 will not block when stored at a suitable room temperature. Keep all rolls in their wrapping until required for processing. Avoid wide variations in temperature and humidity in storage. Temperatures between 18 ℃ – 23 ℃ (64 ℉ – 73 ℉) and a relative humidity between 50%-65% are the best conditions. Providing correct packaging and storage of the reels, we guarantee them for 6 months after passage of risk. The above data represents the averages obtained in our Laboratory. Specification for use and final result’s correspond to our best technical experience but cannot be intended as our commitment of liability. User will determine the suitability of the product and method of application for each specific use. |

Contact

us by phone e-mail for any adhesive tape requirement

Web: www.printernational.co.uk ~ Tel: +44 (0)20 8050 8069 ~ E-mail: pr@printernational.co.uk